|

|

Powerful Aeration System

|

| The suggestion of the efficient the waste water treatment system and reduction of large cost by AERATOR R1 |

|

|

|

| Fertures

|

| 1. Considerable Reduction of Electric Expenses 2. High and Stable Oxygen Absorption Ratio 3. Maintenance free -The Regular Cleaning is unnecessary 4. No Trouble There is not stopped up 5. The Sludge doesn't Pile up in the Tank Bottom 6. The Introduction Construction is EasyReal retirement period by the equipment introduced is 1.5 to 2 |

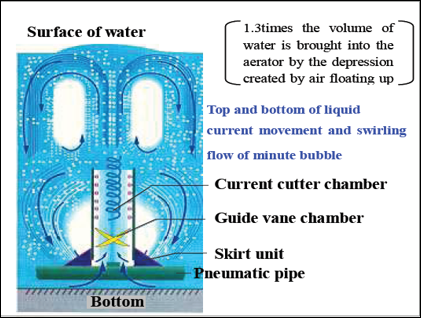

| Overview (Technical principles, actions, etc.)

|

| A static air diffuser without moving parts has been developed for aeration of the active sludge tank |

|

|

| Usage example / result

|

| In Japan, as the aeration device of waste water treatment tank such as dyeing factories and food factories, there is a track record introduced in more than 500 factories. In overseas has introduced track record in food factories and industrial wastewater and palm oil mills, rubber factories, chemical plants, etc. mainly in Southeast Asia. |

Surface aeration system 66kw ⇒ AERATOR R1 system 30kw Electricity bill has been significantly reduced |

SUZUKI SANGYO CO.,LTD. |

3-15 Yamada-Hisadacho,Nishikyo-ku,Kyoto 615-8263,Japan Within Japan Tel : 075-392-7577 Fax:075-392-7527 Overseas: Tel :(81)-75-392-7577 Fax:(81)-75-392-7527 E-mail : |